Cremacaffè works a bit like crowd-sourced design, with the advantage of small-scale production: as soon as we see room for improvement in one of our products, we start working on it, in order to ship the updated stand to our next Customer.

Cremacaffè works a bit like crowd-sourced design, with the advantage of small-scale production: as soon as we see room for improvement in one of our products, we start working on it, in order to ship the updated stand to our next Customer.A couple of months ago, for instance, one of our Clients purchased a KOSMO stand to hold a bigger device than the ones we recommend on our Compatibility List. This started a conversation, and we thought: if we tweak the design just a little bit, we can make the KOSMO sturdier and usable for larger machines, thus our Clients will get more value for their money.

Add that our stands are made of wood, which is sturdier than plastic, because it is made of crossing fibers, yet it is an uneven material, for the very same reason. Making this kind of design fit seamlessly becomes even more complicated, when using wood.

In this scenario, also the smallest change can result into a very long process. We made about 20 prototypes, and once we got a design which presented relevant improvements compared to the old version, we started shipping. Prototyping continued after that, and at the time of writing we have over 30 different models to get to series VI, which is the one currently shipping.

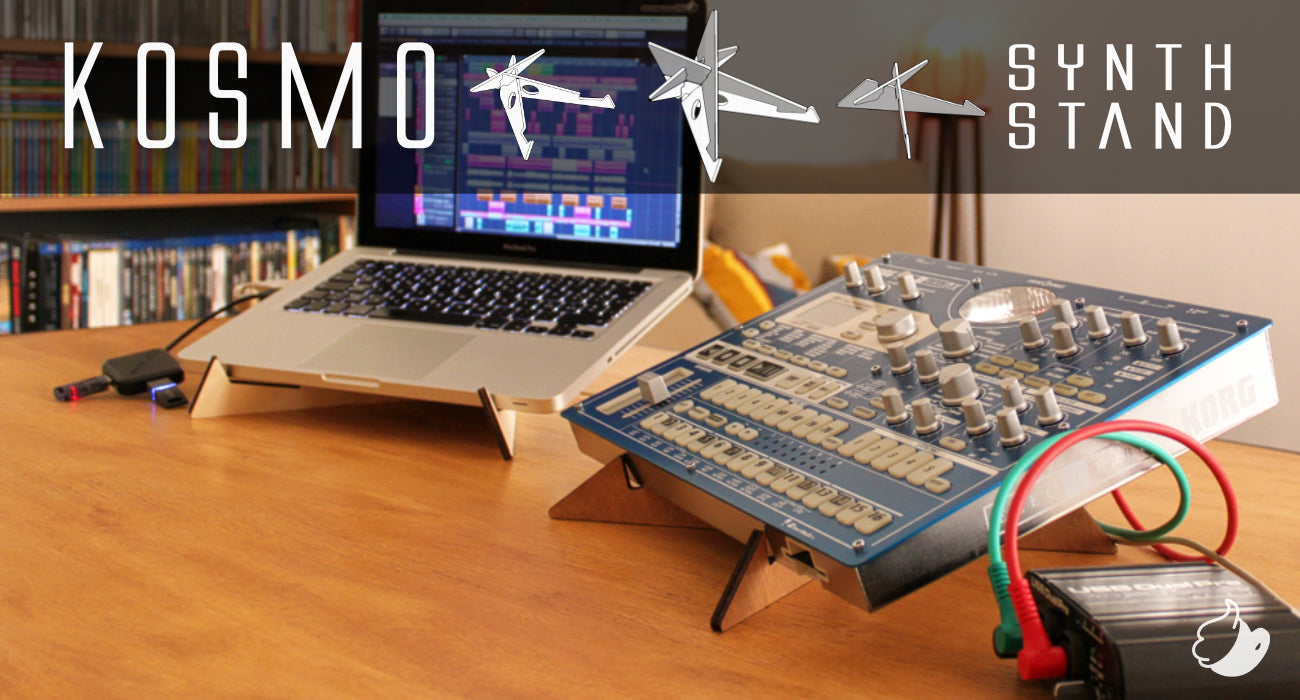

From now on, you will be receiving a new KOSMO stand, with all the features of our original design (two 15° stands which can be used in line, e.g. to hold a keyboard or 2 synths, or on top of each other, at 30°) PLUS: 1) a sturdier support on both stands and more stability for large devices; 2) cable management (holes on one stand, to hide cables beneath it); 3) one more operating angle: by turning one stand in vertical position, you will get a 90° angle, ideal for tablets. The new KOSMO is available at the same price of the previous model.

From now on, you will be receiving a new KOSMO stand, with all the features of our original design (two 15° stands which can be used in line, e.g. to hold a keyboard or 2 synths, or on top of each other, at 30°) PLUS: 1) a sturdier support on both stands and more stability for large devices; 2) cable management (holes on one stand, to hide cables beneath it); 3) one more operating angle: by turning one stand in vertical position, you will get a 90° angle, ideal for tablets. The new KOSMO is available at the same price of the previous model.Here is what Jérémie, which inspired this article, wrote when he first read about it:

“20 prototypes… wow.

I work in films: people never know how much efforts it takes to make a camera move effortlessly in a smooth manner from one point to another. Your design must be affected by the same mechanics: the simpler it looks/feels, the more trials and work you have to put into it.

With KOSMO, the design looks better than the old one. It looks lighter, less massive.

(…) I wish you inspiration and balance.”

That simply made my day. Especially the “lighter, less massive” part, for how it has been achieved - many optical corrections on the middle pieces!

And also, especially, for the sense of understanding, sharing a process across disciplines. That feels great, and makes the work you put into it much, much lighter and happier.

Wishing inspiration and balance to you all!

Elisa & Andrea

Related links:

· KOSMO double stand

. Which Stand for My Device?

· New anti-skid system for all our stands!